Fiber reinforced concrete contains steel, synthetic or natural fibers randomly distributed within the cementitious matrix. The fibers help controlling cracking of the concrete. In particular, UHPFRC (Ultra High-Performance Fiber-Reinforced Concrete) is a material with a compact cementitious matrix reinforced with short steel fibers. UHPFRC is known for its outstanding mechanical performances. It is characterized by a very high compressive strength and a hardening and softening behavior in tension. Moreover, UHPFRC has a very low permeability which makes it very durable when exposed to water and deicing salts.

With its remarkable properties, UHPFRC is appropriate to strengthen and protect existing structures as well as for new structures.

Protection layers

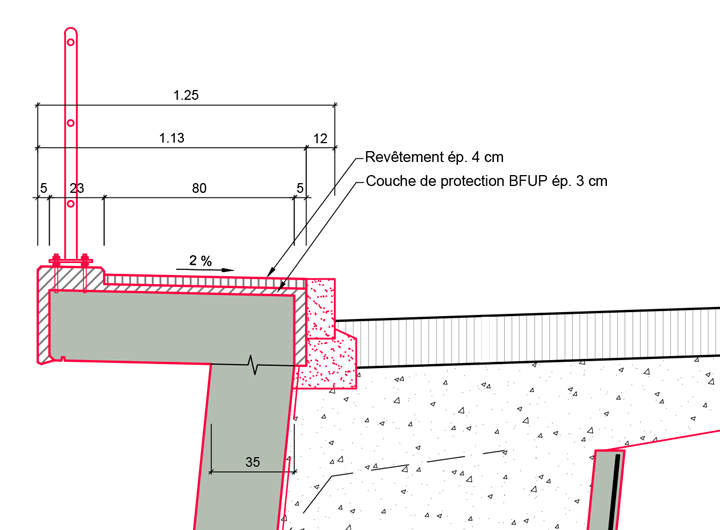

Thanks to its low degree of porosity, UHPFRC is ideal for the protection of structures such as bridges, walkways and piers.

The Montreux corniches have been protected with a 30mm layer of UHPFRC without reinforcement.

Reinforcement Layers

UHPFRC can be applied in thin layers to strengthen structures made from reinforced concrete.

A whole building has been strengthened in Geneva using a layer of UHPFRC cast over a ribbed slab so as to increase the resistance and rigidity of the slab.

Shear Reinforcement

UHPFRC can be used to increase shear resistance of a concrete element.

The deck of the bridge over the Chandelar has been strengthened for shear by filling recesses with fiber-reinforced concrete.

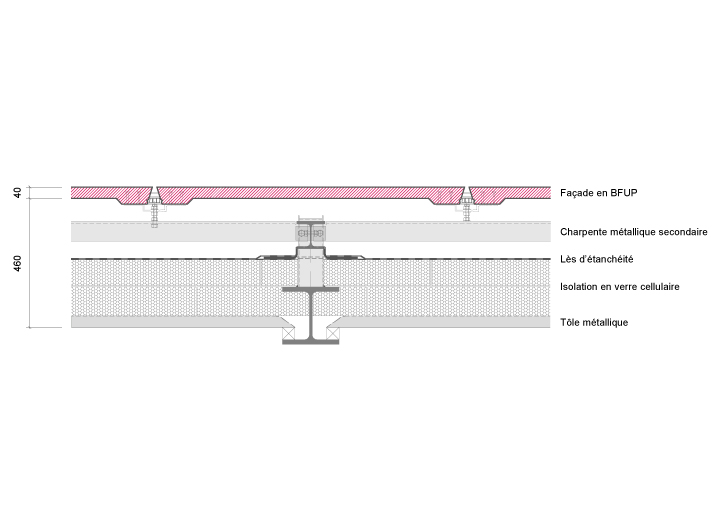

Façade Material

UHPFRC or fiber-reinforced concrete can be used for façades. As a material, it provides a blend of strength, low porosity and finesse.

The façade of the National Museum of Qatar uses pre-fabricated slabs of fiber-reinforced concrete for cladding.

UHPFRC Struts and Shells

UHPFRC can be used for struts or shells.

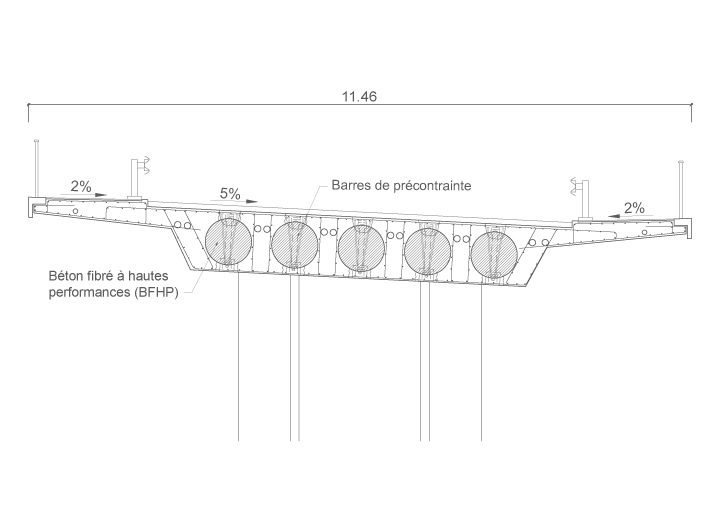

The bridges over the Paudèze were reinforced using prefabricated UHPFRC struts. These concrete bridges were built using the balanced cantilever method. With the new UHPFRC struts, their image could be preserved and modernised. Piror to implementing these new elements, laboratory tests for friction and buckling were performed.